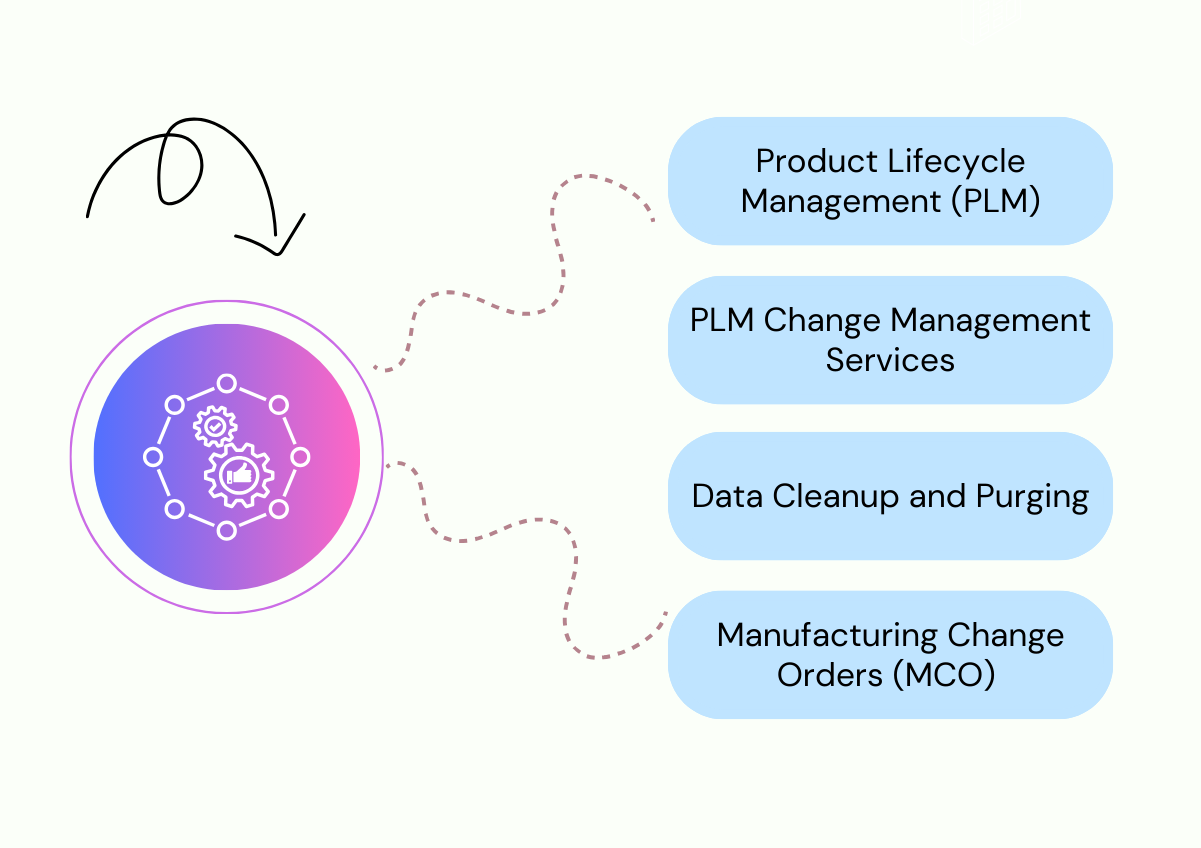

Change Management Support:

Managing and documenting changes within the PLM system, including system enhancements, updates, and adjustments to workflows. This ensures that changes are tracked, approved, and communicated properly.

Managing and documenting changes within the PLM system, including system enhancements, updates, and adjustments to workflows. This ensures that changes are tracked, approved, and communicated properly.

Analyzing and improving existing processes within the PLM system to enhance efficiency, eliminate bottlenecks, and ensure that product data flows smoothly across teams (R&D, design, production, etc.).

Managing the end-of-life (EOL) process for products, including tracking component obsolescence, planning for replacements, and ensuring that the PLM system reflects these changes in product data.

Managing the transition from production to end-of-life, ensuring that all stakeholders are informed of phase-outs, and that supply chain and production planning are adjusted accordingly.

Identifying and deleting old, outdated, or irrelevant data from the PLM system, such as legacy parts, documents, or outdated versions of BOMs (Bills of Materials).

Merging or eliminating duplicate records, such as duplicate part numbers or overlapping product data, to streamline access to critical information and improve system performance.

Reviewing and correcting any errors in data entry, such as inaccurate part specifications, incorrect metadata, or incomplete product information, to ensure data integrity and reduce errors in the design and manufacturing process.